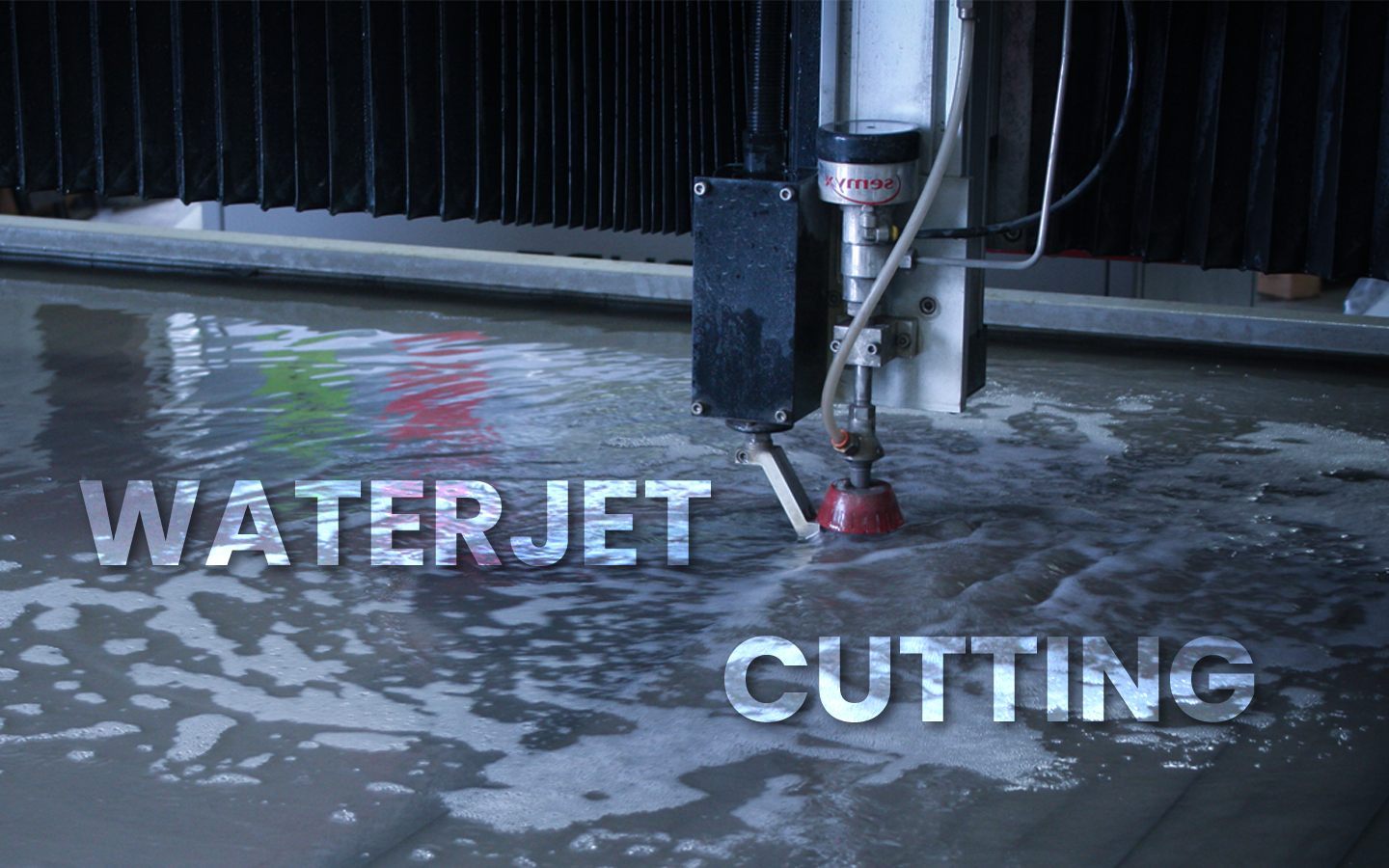

Waterjet cutting services

Waterjet cutting is a cutting-edge technology that has become extremely popular in many industries. It offers extreme precision, versatility and minimal environmental impact, making it a popular choice for material processing companies. What are the main advantages of this method, how does waterjet cutting work and in which applications does it work best? We will try to discuss all of these in detail below.

What is waterjet cutting?

Waterjet cutting, also known as hydroabrasive cutting, is a material processing technique that uses a jet of water at very high pressure to cut through a variety of materials. The water jet is often enhanced with the addition of an abrasive, such as garnet, which increases its effectiveness in cutting harder materials such as steel, stone or ceramics.

The cutting process is, of course, carried out in special CNC (Computer Numerical Control) machines, which provide precise control over the movement of the cutting head. The water, passed through a nozzle with a very small diameter, reaches a speed close to the speed of sound, enabling it to cut through materials efficiently. Water cutting is a so-called ‘cold’ process, which means that the material is not heated during the process, thus eliminating the risk of deformation or alteration of its properties.

Precision and quality of cut

One of the greatest advantages of waterjet cutting is its exceptional precision. Thanks to advanced CNC technology, cutting accuracy of the order of 0.1 mm can be achieved, making it possible to create complex shapes and details with a high degree of accuracy. The water jet is so thin that it allows very precise cuts to be made, even on materials with high hardness.

High cutting quality is another major advantage of this method. The edges obtained by water cutting are smooth and burr-free, minimising the need for additional machining. Unlike laser cutting, waterjet cutting also does not result in scorching or thermal distortion, which is particularly important for temperature-sensitive materials.

Versatile applications

Waterjet cutting has become an extremely versatile technology that is used in many industries. It can be used to process a wide range of materials, from soft materials such as rubber or plastics to very hard materials such as metals, stone, glass, ceramics or composites.

In the construction and architectural industry, waterjet cutting is also often used to precisely shape components made of stone, marble or granite. With this technology, it is possible to create intricate patterns, inlays or precise cut-outs in stone slabs, which are used in interior finishes and building facades.

In the metal and automotive industries, waterjet cutting is used for precision machining of sheet metal, pipes, and structural components that require high accuracy. This technology allows for the machining of materials of different thicknesses, which makes it particularly appreciated in the production of mechanical components, car bodies and also machine parts.

Technological advantages of waterjet cutting

Water jet cutting also stands out from other processing methods in terms of its operational flexibility. This is because waterjet cutting machines can operate continuously and are therefore able to process both large and small batches of material. They are also excellent at handling different material thicknesses without the need to change tools. This makes such technology ideal for both prototype production and mass production.

In addition, waterjet cutting machines can be programmed to handle the most complex designs, including unusual shapes, angles and patterns. This makes waterjet cutting a popular choice for projects that require a high degree of precision and creativity.

Cost and efficiency

Although waterjet cutting technology may seem expensive at first glance, it is actually an investment that pays for itself quickly. Waterjet cutting machines, although more expensive to purchase, have low running costs and a long service life. In addition, the lack of additional machining and minimal material consumption translate into significant savings in the long term.

It is also worth noting that due to its versatility, waterjet cutting allows for a wide range of projects, making this technology a versatile tool in the arsenal of any material processing company.

The future of waterjet cutting technology

Waterjet cutting is undoubtedly a technology that will develop rapidly in the coming years. As technology advances, we can expect even greater precision, speed and adaptability from this method. Also, increasing environmental awareness and the need for sustainable technologies in industry will make waterjet cutting a standard in many industries.