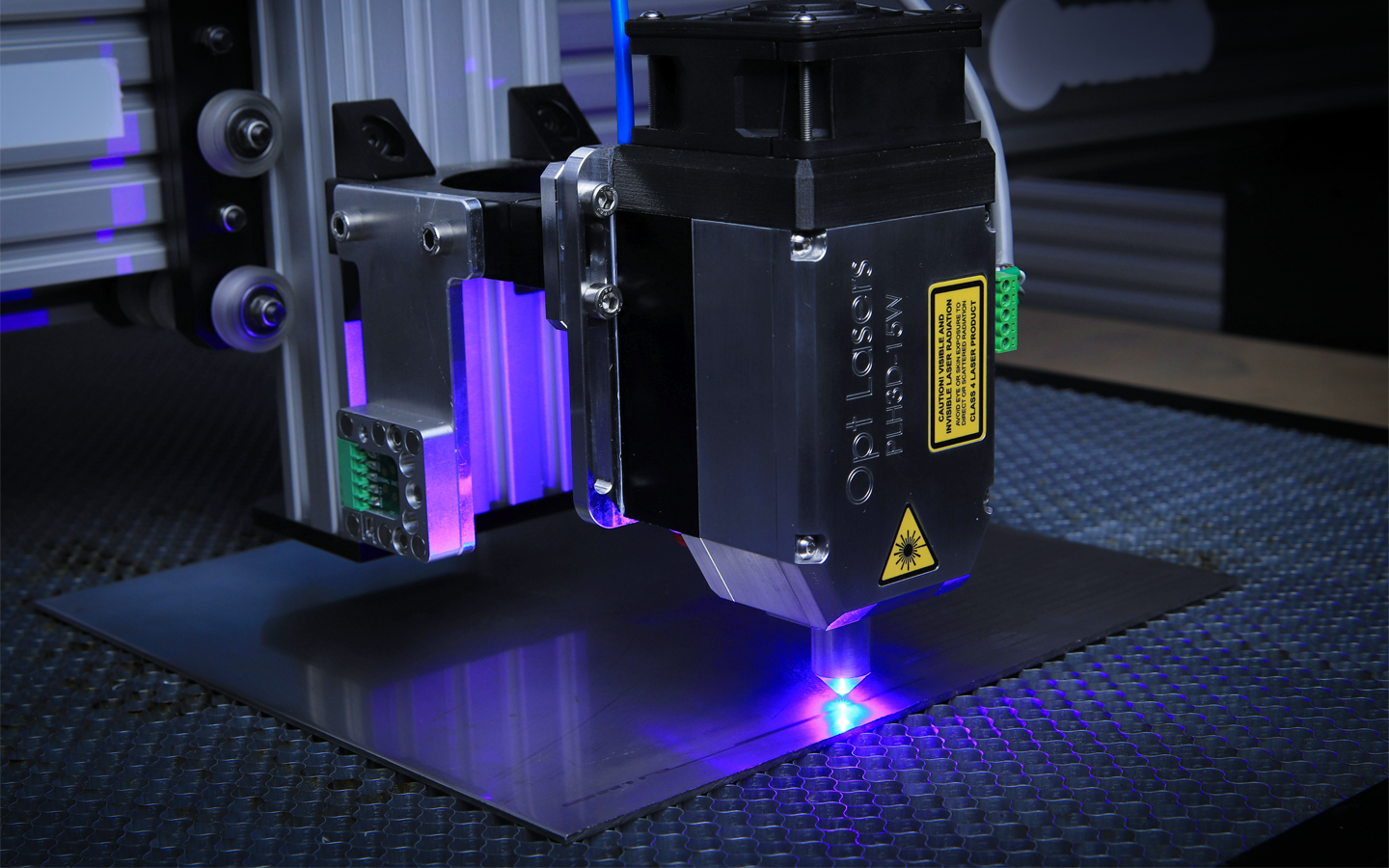

CNC, or Computer Numerical Control, machines have revolutionised many industries by enabling the precise and rapid processing of materials. Their versatility means that they are currently used in a wide range of applications – from the production of automotive components to the creation of artistic designs.

Due to the continuous development of this branch of manufacturing, we have decided to present below five of the most important applications of CNC machines, which show how crucial a role they play in today’s industry.

Automotive industry

One of the main applications of CNC machines is in the automotive industry. Thanks to their precision and repeatability, CNC machines are used to manufacture many key automotive components. This is because processes such as milling, turning and drilling make it possible to produce parts with complex shapes and extremely high accuracy. In the automotive sector, this is how pistons, crankshafts, gearbox housings and suspension components, among others, are produced.

In this sector, it is not only quality that counts, but also production efficiency. This is why CNC machines that can run continuously for many hours are so well suited, allowing components to be mass-produced with a high degree of accuracy. By automating the process, CNC machines furthermore minimise the risk of human error, which is crucial in the production of safety- and function-critical components for vehicles.

Aerospace industry

In the aerospace industry, there is no room for compromise when it comes to quality and precision. CNC machines are therefore indispensable for the production of components that must meet extremely high requirements in terms of strength and dimensional tolerances. Parts such as aero-engine components, turbines, wing structures and other complex assemblies are manufactured using CNC machines.

Due to the variety of materials used – from lightweight aluminium alloys to robust titanium components – CNC machines must be able to cope with machining both soft and hard materials. In the aerospace industry, precision to thousandths of a millimetre is ultimately the norm, and CNC machines excel at achieving such requirements.

Medical industry

CNC machines are also widely used in the medical field, especially in the production of medical equipment and implants. Thanks to precision machining, such machines make it possible to produce parts of very small sizes and complex shapes, which is crucial in the production of surgical instruments, prostheses, joint or dental implants.

In particular, implants, which must be perfectly adapted to the patient’s anatomy, are produced on CNC machines with the highest precision. Such a process involves machining biocompatible materials such as titanium or ceramic, which are durable and safe for use in the human body. CNC technology also enables rapid prototyping, which accelerates the development of modern medical solutions.

Electronics industry

Precision and small scale are also key in the electronics industry, where CNC machines are used to produce components with very small dimensions, such as housings, connector components or cooling systems. Production speed and precision are crucial here, as these components must fit perfectly with other electronic parts.

CNC machines make it possible to manufacture components from conductive and insulating materials, which is crucial in the production of components for computers, mobile phones and other advanced electronic devices. The use of CNC technology also makes it possible to create specialised tools for the production of microcircuits and other complex electronic components.

Arts and furniture industry

Although the art and furniture industry may seem less technically advanced than the other industries mentioned above, CNC machines play an important role here too. This is because they make it possible to cut intricate patterns, details and forms in a variety of materials – from wood to metal to plastic. CNC allows artists and designers to realise unique designs with high precision that would be difficult or impossible to do by hand.

In the furniture industry, CNC machines are used to produce custom-shaped furniture components, cut out decorative patterns, and to quickly and accurately create pieces with intricate details. The ability to machine wood, metal or plastic with precision opens up new possibilities in the design and production of furniture with unique designs.