Properties of stainless steel.

Stainless steel is a material that has enjoyed unwavering popularity in many industries for many decades. Its unique properties make it widely used, for example in construction, the food industry, medicine, the automotive industry and even in the arts. So what is stainless steel, what makes it special and why is it so popular with engineers and designers the world over? The answer to these questions can be found in the following article.

What is stainless steel?

Stainless steel is nothing more than a type of steel alloy that contains at least 10.5% chromium. It is this element that is responsible for its corrosion resistance, which is one of the most important characteristics of the material. Compared to other types of steel, stainless steel also has a higher nickel content, which further increases its resistance to external influences.

Depending on its chemical composition and internal structure, stainless steel can come in different variants. The most common are austenitic steel, ferritic steel, martensitic steel and duplex steel. Each of these varieties has its own unique properties that determine its use in specific conditions.

Corrosion resistance.

One of the most important strengths of stainless steel is its resistance to corrosion. It owes this, as we mentioned a little above, to the presence of chromium, which reacts with oxygen and forms a thin passive layer on the surface of the steel. This invisible layer effectively protects the material from further corrosive influences such as moisture, acids or alkalis. Importantly, even in the event of mechanical damage to the stainless steel surface, the passive layer renews itself, providing continuous protection.

Corrosion resistance, moreover, makes stainless steel particularly valuable in chemically aggressive environments, as well as where high humidity is present. Examples of applications include chemical installations, marine structures, as well as architectural elements exposed to the weather.

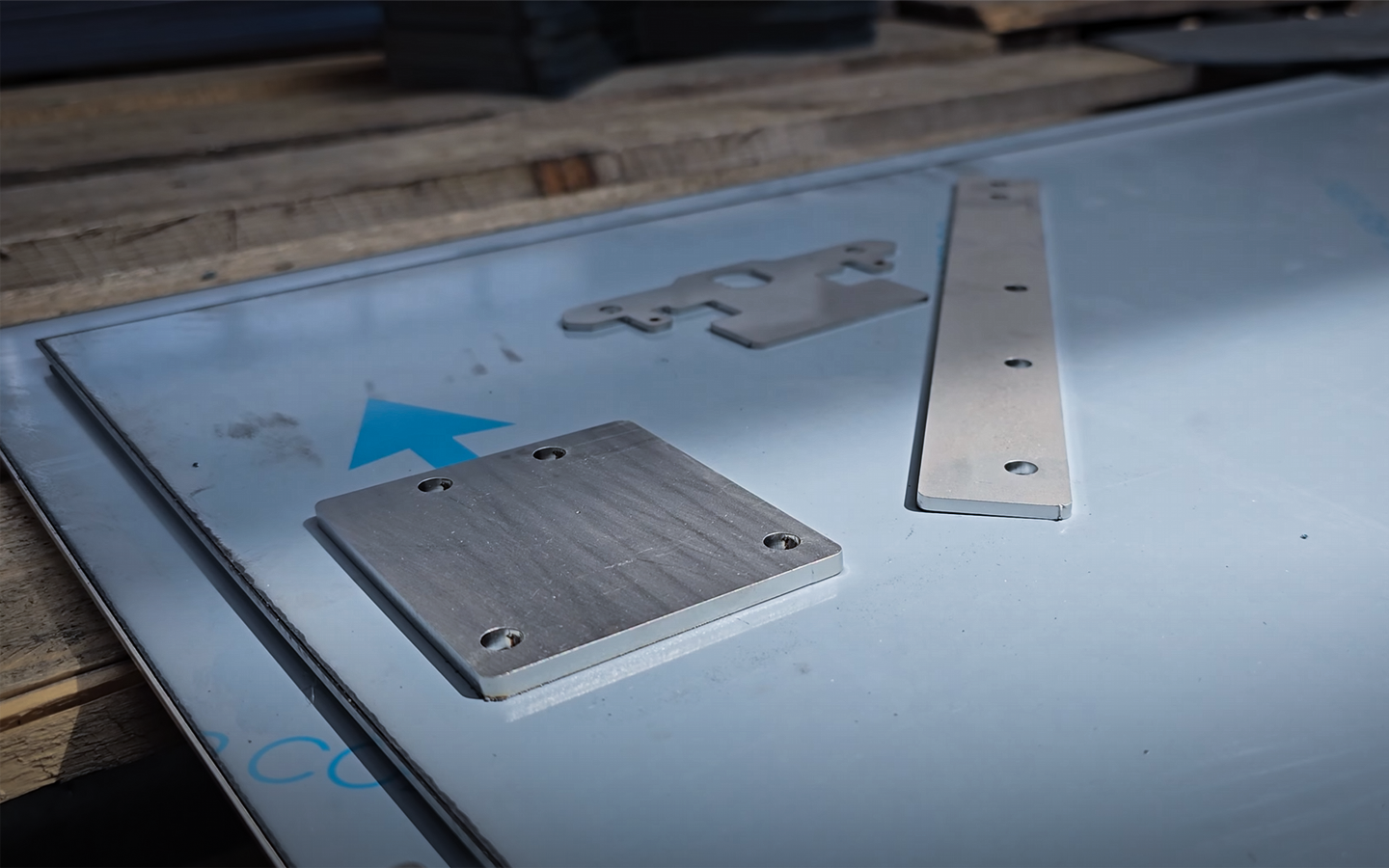

Aesthetics and surface finish.

Another important aspect of stainless steel is its aesthetic appearance. This is because it has a sleek, modern finish that is both durable and easy to keep clean. Stainless steel can be polished, brushed, matt or shiny, allowing its appearance to be tailored to different design needs.

Moreover, thanks to its aesthetic properties, it has found its way into architecture and interior design. It is used for balustrades, wall cladding, kitchen appliances and decorative elements, among other things. Its high scratch resistance and ease of cleaning make it an ideal choice in areas where both functionality and appearance are important.

Stainless steel is also characterised by its high mechanical strength, making it an extremely durable and damage-resistant material. Depending on the type of stainless steel, the material can have different mechanical properties. For example, austenitic steel, which is the most common type of stainless steel, has high tensile and impact strength, as well as excellent ductility.

The high mechanical strength of stainless steel makes it suitable for use in structures where high load-bearing capacity and durability are required, such as in bridges, towers and building load-bearing components. This makes stainless steel a material that can be successfully used in the most demanding conditions.

Hygiene and safety in the food industry and medicine.

It is worth mentioning that stainless steel is a material that has found wide application in the food industry and medicine due to its hygienic properties. It is resistant to corrosion, easy to clean and does not react with food or other substances, making it an ideal material for the manufacture of crockery, kitchen appliances, as well as surgical and medical instruments.

The smooth surface of stainless steel minimises the risk of bacteria and other micro-organisms settling, which is crucial in areas where high cleanliness is required. As a result, stainless steel is widely used in the manufacture of laboratory furniture, food processing equipment and in water and wastewater systems.

Recycling and ecology.

Stainless steel is ultimately an environmentally friendly material because it is fully recyclable. At the end of a stainless steel product’s life cycle, the material can be recycled and reused without losing its properties. The high recycling rate makes stainless steel a sustainable material that minimises the negative impact on the environment.

Increasing environmental awareness makes stainless steel a popular choice for projects that aim to reduce the carbon footprint and promote sustainability. As a result, the material is considered one of the greenest choices in construction and industry.