Laser cutting for hobbyists

In recent years, laser cutting has become one of the most technologically advanced activities in many industries. On the other hand, due to this development, it is now also a fascinating and versatile tool available to hobbyists. After all, a technology that was once reserved only for large production facilities has become available to a wide range of users, making precise and complex projects possible in the comfort of their own home. But what makes laser cutting so special and how can it be used for amateur projects? Here’s everything you need to know.

What is laser cutting?

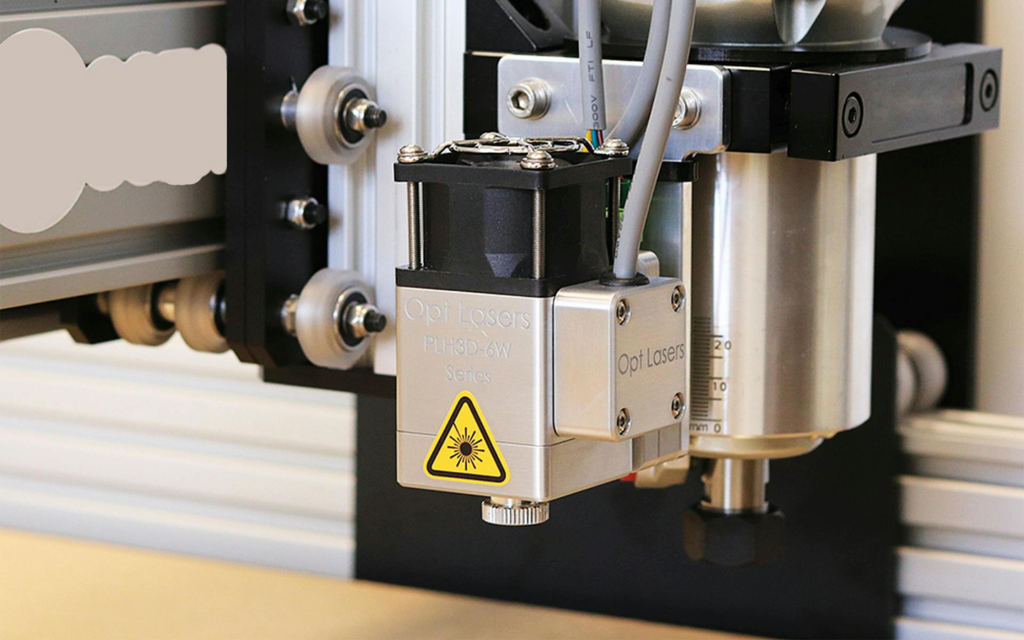

Laser cutting is nothing more than a material processing process that uses a concentrated laser beam to precisely cut, engrave or mark various materials such as wood, plastic, metal, leather or fabric. Unlike traditional cutting methods, the laser enables the creation of extremely accurate and intricate designs with minimal risk of damaging the material.

The laser beam is generated by a laser machine that converts electrical energy into a concentrated beam of light. The beam is then directed through a system of mirrors or lenses onto the material, where it concentrates its energy in a small area, causing rapid heating, melting and vaporisation of the material.

Why should you be interested in laser cutting?

There are many reasons for taking an interest, even on a hobbyist level, in laser cutting. Among the main ones, however, we can undoubtedly include:

Precision and accuracy – one of the main reasons why hobbyists have become so fond of laser cutting is its ability to create extremely precise cuts. The ability to control the laser beam to within a fraction of a millimetre makes it the ideal tool for projects requiring a high level of detail.

Material versatility – laser cutting machines can work with a wide variety of materials. Whether you are creating architectural models from cardboard, engraving leather phone cases or cutting thin sheets of metal for sculptural projects, the laser can handle it with ease.

Safe and clean working environment – unlike traditional power tools, laser cutting does not generate splatter or chips, which in turn minimises the risk of injury and keeps the workplace clean. Additionally, many home laser machines have ventilation and filtration systems to eliminate fumes and vapours.

Ease of use and software availability – today’s laser cutting machines are often equipped with intuitive software that allows users to easily design and edit patterns. Many of these programs are compatible with popular image file formats, making it even easier to get started.

How do you get started with laser cutting?

Starting a laser cutting adventure as a hobby can be exciting, but it’s worth starting with a solid foundation. Here are some steps to help you get started:

1. Choose the right equipment – there are many laser models on the market to suit different needs and budgets. For beginner hobbyists, compact CO2 lasers with less power may be the ideal choice, which are sufficient for working with materials such as wood, leather or acrylic. If you plan to work with metals, it will be necessary to purchase a higher-powered laser, such as a fibre laser (fiber laser), which, however, will not be as safe for beginners working in the privacy of their homes.

2. Understand basic safety rules – although laser cutting is relatively safe, there are some rules to follow. Always wear safety glasses, avoid direct skin contact with the laser beam and make sure the room is well ventilated.

3. Learning how to use the software – learning how to use laser design and control software is key. Many programs offer online tutorials to help you understand how to create and edit designs, as well as how to control cutting parameters such as laser power and cutting speed.

4. Experimenting with materials – before you move on to more advanced designs, it is worth experimenting with different materials and laser settings. This will give you a better understanding of how different materials react to laser cutting, as well as which parameters are most suitable for the type of work.