How CNC Laser Cutting is Transforming Modern Manufacturing

In today’s fast-paced industrial landscape, precision, efficiency, and adaptability are essential for maintaining competitiveness. As manufacturing processes evolve, companies are increasingly turning to advanced technologies to meet rising demands and enhance production capabilities. One such technology that has emerged as a game-changer in the manufacturing world is CNC laser cutting. By combining the power of computer numerical control (CNC) with the precision of laser technology, CNC laser cutting has revolutionized modern manufacturing across a wide range of industries.

In this article, we will explore how CNC laser cutting works, its key benefits, and how it is transforming modern manufacturing processes.

What is CNC Laser Cutting?

CNC laser cutting is a highly precise and automated method of cutting materials using a focused laser beam. The term “CNC” stands for “computer numerical control” which refers to the use of computer systems to control and automate cutting processes. In CNC laser cutting, a computer is programmed with a specific set of instructions (or a “G-code”), which tells the machine exactly how to cut, drill, or engrave materials with incredible accuracy.

This technology can be used on a wide variety of materials, including metals, plastics, wood, glass, and even textiles. It allows for intricate designs, smooth edges, and highly detailed cuts that are difficult or impossible to achieve with traditional methods.

How CNC Laser Cutting Works

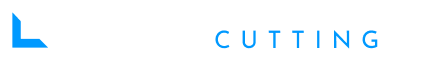

The CNC laser cutting process begins with a computer program that translates a digital design file into instructions for the laser cutting machine. This file is typically created using computer-aided design (CAD) software, where designers or engineers create precise models of the desired parts or products.

Once the design is complete, the machine receives the instructions and uses a powerful laser to cut or engrave the material. The laser emits a concentrated beam of light that melts, burns, or vaporizes the material, depending on its type and thickness. An assist gas (usually oxygen or nitrogen) is used to blow away any debris, ensuring a clean and precise cut.

CNC laser cutting machines can operate with astonishing precision, achieving tolerances as tight as ±0.1 mm, which makes them ideal for industries that require high levels of accuracy, such as aerospace, automotive, and electronics.

The Key Benefits of CNC Laser Cutting

1. Precision and Accuracy

One of the most significant advantages of CNC laser cutting is its unparalleled precision. The combination of CNC technology and laser power allows manufacturers to achieve highly accurate cuts, even for complex and intricate designs. Traditional cutting methods, such as mechanical cutting or plasma cutting, often struggle to match the fine detail and sharpness of laser-cut components.

This precision is particularly important for industries where small variations in measurements can lead to significant issues in assembly or product functionality. For example, in the aerospace industry, even a slight deviation from the design can result in parts that do not fit or function as intended. CNC laser cutting helps prevent these errors, reducing waste and the need for rework.

2. Speed and Efficiency

CNC laser cutting machines are incredibly fast, especially when compared to traditional cutting methods. Once the cutting program is set, the machine can operate continuously, cutting materials at high speeds with minimal manual intervention. This increased efficiency helps manufacturers meet tight production schedules, reduce lead times, and increase overall productivity.

In addition, CNC laser cutting can handle high-volume production runs with ease. Since the process is automated, the same design can be replicated with perfect consistency across thousands of units. This makes it an ideal solution for mass production in industries like automotive, electronics, and consumer goods.

3. Material Versatility

One of the standout features of CNC laser cutting is its ability to work with a wide range of materials. From metals like steel, aluminum, and titanium to non-metallic materials like wood, plastic, and acrylic, CNC laser cutting can be applied to various substrates with equal effectiveness. This versatility allows manufacturers to use the same technology across multiple product lines, reducing the need for different cutting equipment.

Moreover, laser cutting can handle materials of varying thicknesses, making it suitable for both thin sheets and thicker plates. Whether you’re cutting intricate parts from thin metal or producing sturdy components from heavy-duty materials, CNC laser cutting offers the flexibility needed to meet diverse production requirements.

While the initial investment in CNC laser cutting equipment may be higher than some traditional cutting methods, the long-term cost savings are substantial. Because CNC laser cutting is highly automated, it reduces the need for manual labor, which can significantly lower labor costs over time.

Additionally, the precision of laser cutting minimizes material waste. Traditional cutting methods often result in excessive material loss due to inaccuracies, but CNC laser cutting ensures that materials are used efficiently, reducing the amount of scrap generated during production. This not only helps control costs but also supports sustainable manufacturing practices by reducing the environmental impact of waste.

5. Reduced Tool Wear and Maintenance

Unlike mechanical cutting methods that involve direct contact with the material, CNC laser cutting is a non-contact process. This means there is no physical wear and tear on cutting tools, resulting in less maintenance and longer equipment lifespan. Traditional methods like saws or drills can wear out quickly, requiring frequent replacement or sharpening of blades and tools. Laser cutting eliminates this issue, allowing machines to operate for extended periods without the need for costly repairs or replacements.

CNC laser cutting is playing a pivotal role in transforming the way modern manufacturing operates. By offering a combination of precision, speed, and versatility, this technology is enabling manufacturers to meet the growing demands of various industries while maintaining high standards of quality and efficiency.

1. Revolutionizing Customization

In the past, mass production often meant sacrificing customization, as traditional methods struggled to efficiently produce unique or custom designs. However, CNC laser cutting has changed this dynamic by allowing manufacturers to easily create customized components without sacrificing speed or efficiency. Whether it’s personalized products, limited edition designs, or one-off prototypes, CNC laser cutting makes customization a viable option for industries that need to cater to specific customer preferences.

This has been especially transformative in industries like fashion, interior design, and consumer electronics, where personalized products are becoming increasingly popular.

2. Enhancing Prototyping and Rapid Development

The rise of CNC laser cutting has also accelerated the prototyping process, allowing companies to bring new products to market faster. Engineers and designers can now create prototypes with high precision, test their functionality, and make adjustments in real-time. This rapid iteration process significantly reduces the time it takes to move from concept to production, giving businesses a competitive edge in fast-moving markets.

By enabling quick and accurate prototyping, CNC laser cutting helps companies reduce development costs and avoid potential design flaws before full-scale production begins.

3. Supporting Green Manufacturing

As sustainability becomes a key focus in manufacturing, CNC laser cutting is helping companies reduce their environmental impact. The precision of laser cutting minimizes material waste, while its energy-efficient operation contributes to lower overall energy consumption. Additionally, the ability to cut materials without the need for harsh chemicals or lubricants further supports eco-friendly manufacturing practices.

In a world where consumers and industries alike are demanding more sustainable solutions, CNC laser cutting is positioning itself as a key player in green manufacturing.

Conclusion

CNC laser cutting is transforming modern manufacturing by providing unmatched precision, speed, and versatility. Its ability to handle a wide range of materials, reduce waste, and lower production costs makes it an invaluable tool for industries across the board. From revolutionizing customization and prototyping to supporting sustainable practices, CNC laser cutting is not only shaping the future of manufacturing but also helping companies stay competitive in an increasingly demanding market.

As this technology continues to evolve, its role in modern manufacturing will only become more integral, driving innovation and efficiency for years to come.

Photo by Opt Lasers from Poland: https://www.pexels.com/photo/close-up-shot-of-cnc-lasers-7254415/

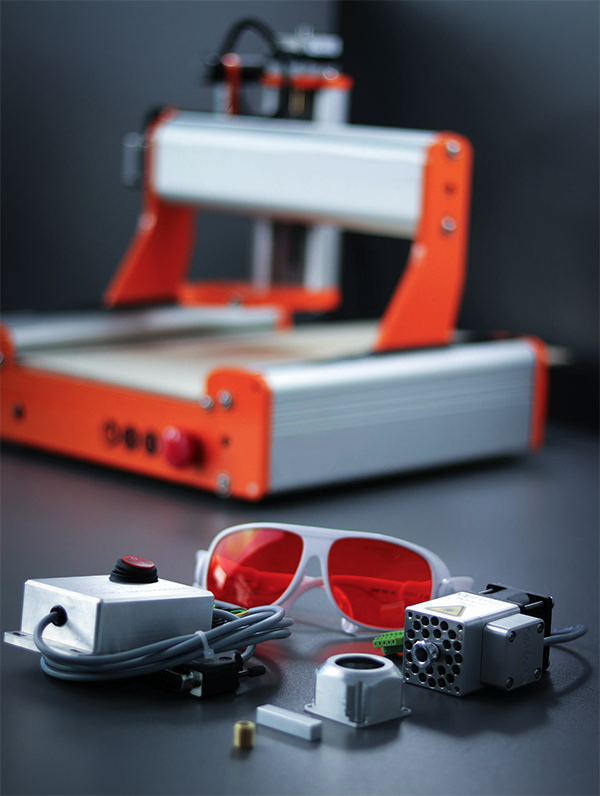

Photo by Opt Lasers from Poland: https://www.pexels.com/photo/close-up-shot-of-a-cnc-laser-machine-7668267/

Photo by Opt Lasers from Poland: https://www.pexels.com/photo/orange-and-white-plastic-frame-sunglasses-7254412/

Photo by Donald Tong: https://www.pexels.com/photo/blue-dynamic-wallpaper-325649/