The benefits of laser cutting for your business

Laser cutting is a technology that is gaining increasing popularity in various industrial sectors. It is used in metallurgy, automotive, electronics, advertising and the construction sector, among others. Its versatility, precision and efficiency mean that more and more companies are choosing to implement it. Therefore, below we will try to outline what benefits laser cutting can bring to your company and why you should consider introducing it into your production processes.

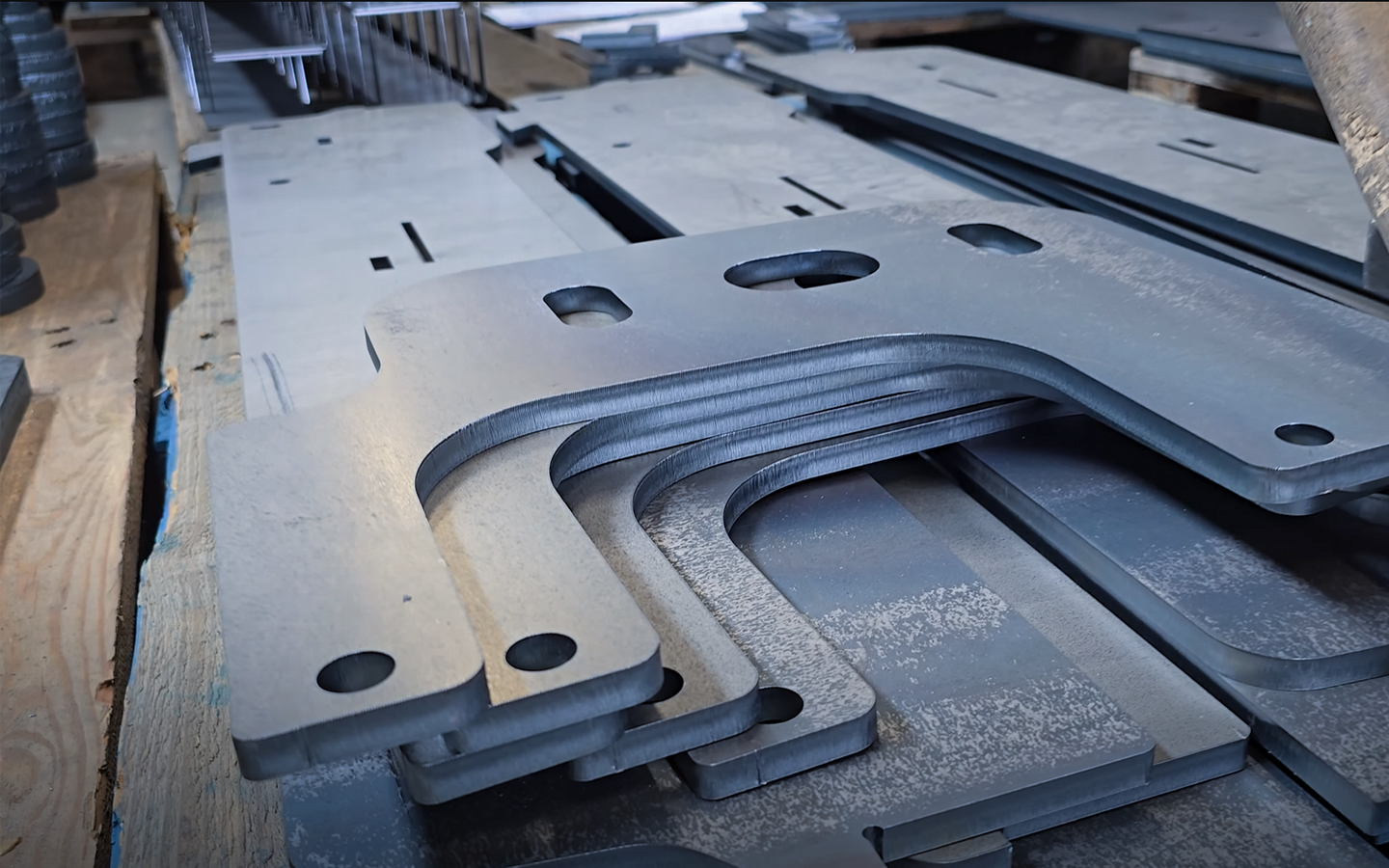

One of the biggest advantages of laser cutting is its incredible precision. With laser technology, it is possible to achieve very thin and accurate cuts, which is particularly important in the production of parts that require high precision, such as machine parts, decorative elements or electronic components. The laser makes it possible to cut to hundredths of a millimetre accuracy, allowing the production of complex shapes and details that are difficult to achieve with traditional cutting methods.

Thanks to the high precision of laser cutting, products are free of bumps and burrs, minimising the need for further processing such as grinding or polishing. This, in turn, saves time and production costs, as well as higher quality of the final product, which is crucial for customer satisfaction.

Increased production efficiency

Laser cutting is a technology that allows for a significant increase in the efficiency of production processes. Thanks to their automation and speed, laser machines are able to process large amounts of material in a short time, speeding up order fulfilment. In addition, the lack of frequent tool changes and the minimal need for maintenance make laser cutting an extremely efficient solution.

Companies that have introduced laser technology into their production processes are reporting significant productivity gains. With the ability to process orders quickly, they can offer competitive delivery times, resulting in greater customer satisfaction and a better position in the market.

Saving material and reducing waste

One of the key challenges facing manufacturing companies is the efficient use of materials and the minimisation of waste. Laser cutting is an extremely advantageous technology in this respect. This is because laser machines are able to cut complex shapes with minimal material waste. As a result, there is significantly less waste compared to traditional cutting methods such as mechanical shears or saws.

The material savings in turn translates directly into lower production costs, which is particularly important when cutting expensive metals such as stainless steel or aluminium.

Versatile applications

Laser cutting is also a technology that is characterised by its remarkable versatility. It can be used to cut a variety of materials such as metals, wood, plastics and even fabrics. As a result, it is used in a wide range of industries, from heavy industry to furniture manufacturing to the advertising industry.

Thanks to the versatility of laser cutting, your company is able to handle a wide range of projects, from simple structural components to complex custom orders.

Safety and reliability

Laser cutting is characterised by a high level of safety and reliability. Modern laser machines are equipped with advanced control systems that minimise the risk of malfunctions and ensure safe operation for operators. In addition, laser cutting does not require the use of mechanical cutting tools, which reduces the risk of material damage and workplace accidents.

The high reliability of laser machines ultimately translates into minimised production downtime, which is key to maintaining production continuity and on-time delivery of orders.

Costs versus investment in laser cutting

While an investment in laser cutting technology may seem costly, consider its long-term benefits. High productivity, material savings, reduced operating costs and the ability to complete complex projects make laser cutting an investment that pays off quickly.

Companies that have decided to implement this technology often see a significant increase in profitability and an improvement in their market position. In the long term, such an action reduces production costs, increases efficiency and improves product quality, which naturally translates into customer satisfaction and higher profits.