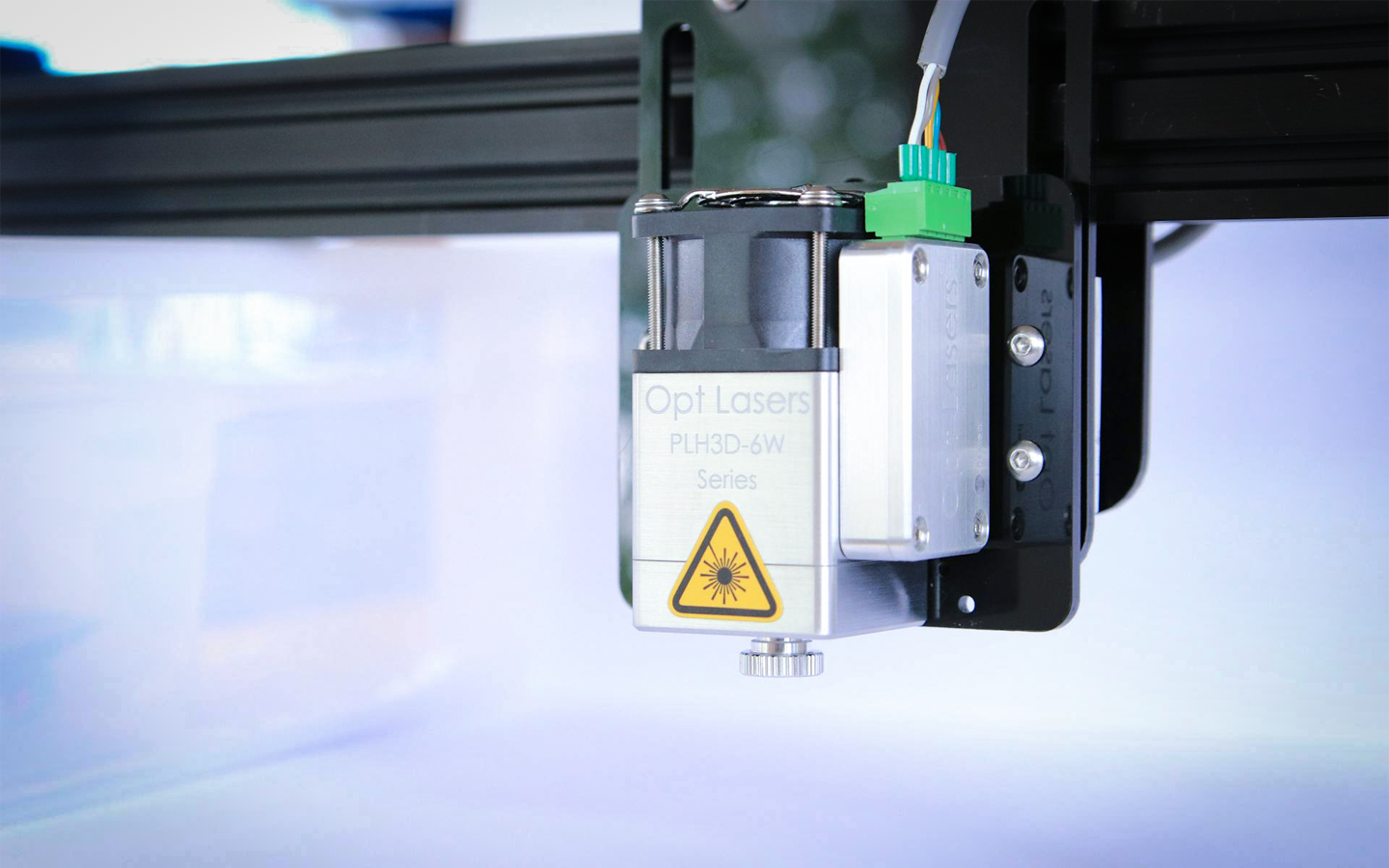

Sustainable Practices: Reducing Waste with Laser Cutting Technology

In an era where environmental concerns are at the forefront of every industry, sustainability has become a critical focus. As companies seek to minimize their environmental footprint, adopting cutting-edge technologies that promote efficiency and reduce waste is essential. One such technology that has made a significant impact in this regard is laser cutting. Known for its precision and versatility, laser cutting is not only revolutionizing manufacturing processes but also contributing to a more sustainable future by significantly reducing material waste.

How Laser Cutting Promotes Sustainability

1. Precision Cutting Minimizes Waste

In an era where environmental concerns are at the forefront of every industry, sustainability has become a critical focus. As companies seek to minimize their environmental footprint, adopting cutting-edge technologies that promote efficiency and reduce waste is essential. One such technology that has made a significant impact in this regard is laser cutting. Known for its precision and versatility, laser cutting is not only revolutionizing manufacturing processes but also contributing to a more sustainable future by significantly reducing material waste.

2. Optimized Material Utilization

Laser cutting technology allows for the optimal use of materials through processes such as nesting, where parts are arranged on the material sheet in a way that minimizes off-cuts. By maximizing material usage, manufacturers can reduce the amount of raw material needed for production. This not only lowers costs but also conserves valuable resources, further promoting sustainability in production practices.

Another aspect of laser cutting that supports sustainability is its energy-efficient operation. Unlike traditional cutting methods that may require multiple tools or high levels of mechanical force, laser cutting uses focused energy in a highly efficient way. Modern laser cutting machines are designed to consume less power while delivering high-quality cuts, which contributes to a lower overall energy footprint during production.

4. Reduced Need for Tooling and Maintenance

Traditional manufacturing methods often rely on specialized tools that wear down over time, leading to frequent replacements and increased waste. In contrast, laser cutting technology eliminates the need for physical tools. The cutting process is non-contact, meaning there is no wear and tear on equipment. This reduces the need for frequent tool replacements and the associated waste, further aligning with sustainability practices.

Laser cutting can be applied to a wide range of materials, from metals to plastics, wood, and even textiles. Its versatility makes it an ideal choice for companies looking to streamline production and reduce waste across multiple sectors. By using one technology to handle various materials, manufacturers can minimize the need for multiple processes, reducing both energy consumption and material waste, contributing to a more sustainable production model.

The Role of Laser Cutting in a Sustainable Future

As the demand for eco-friendly solutions continues to rise, industries must adopt practices that prioritize sustainability. Laser cutting technology offers a way to produce high-quality products while minimizing waste, conserving resources, and reducing energy consumption. These advantages not only benefit the environment but also provide economic incentives for companies looking to lower costs and improve efficiency.

Incorporating laser cutting into a company’s production processes is a step towards a more sustainable future. By reducing material waste, optimizing resource usage, and lowering energy consumption, laser cutting is helping industries across the globe meet the growing demand for environmentally responsible practices.

Conclusion

Laser cutting technology is more than just a tool for precision manufacturing; it’s a crucial component of the broader effort toward sustainability. By minimizing waste, optimizing resource usage, and promoting energy efficiency, laser cutting is paving the way for a greener, more responsible approach to production. For companies committed to reducing their environmental impact, investing in laser cutting technology is a powerful step toward a more sustainable future.

Photo by Opt Lasers from Poland: https://www.pexels.com/photo/close-up-shot-of-engraving-laser-machine-7668273/